-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrate

- KSM bellows

- Cryotechnology, Polycold

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine">

-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrate

- KSM bellows

- Cryotechnology, Polycold

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine

- The Equipment Related Business

- Electronic Device Business

- Ferrotec Europe GmbH Official Distribution

- Photovoltaic Related Products

- Other Related Business

Other Related Business

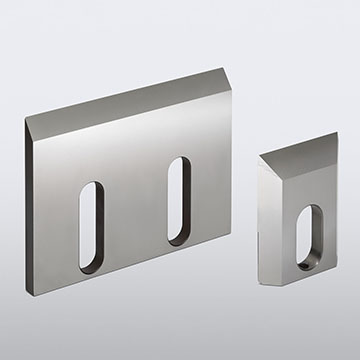

Industrial

Knives and Cutters

Since its establishment in 1925, TOYO KNIFE has accumulated a great deal of expertise in manufacturing industrial knives to meet the diverse needs of its customers.

With high-quality, high-precision products for cutting all kinds of objects and highly functional services, we provide more value to our customers.

Metal foil, Film and Tape

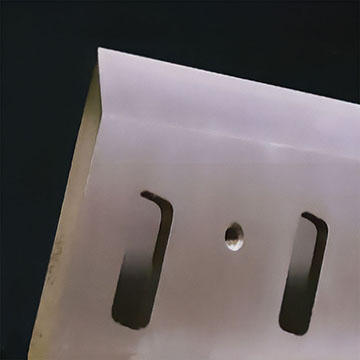

The slitting process is indispensable for cutting long sheet materials, and it covers a wide range of material types, as well as raw material widths and slit widths.

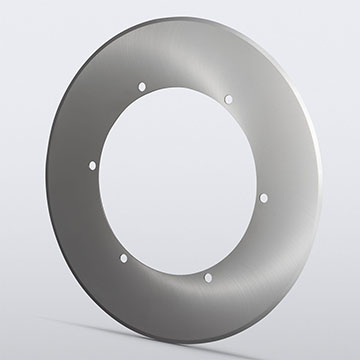

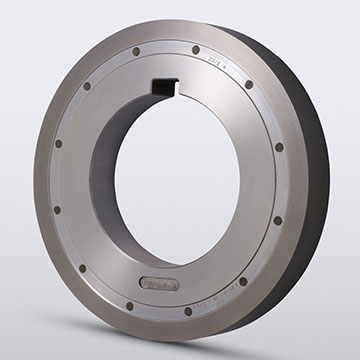

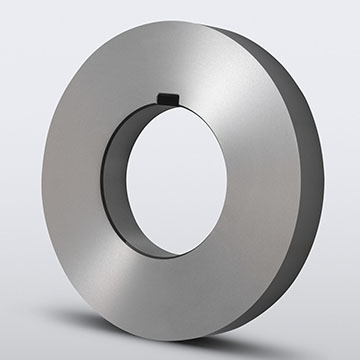

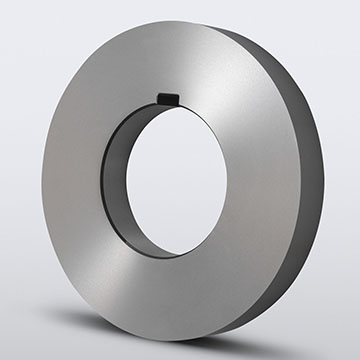

Slitter knives (upper and lower knives) are suitable for slitting thin materials, and the standard method is to use the upper and lower knives with zero(”0”)clearance (no gap).

Based on our half-century of experience and data obtained from various tests, we provide knives that meet users’ needs and contribute to improving the quality of all kinds of products in various industrial fields.

We provide knives according to the specifications of the order, such as the finishing accuracy of the knife edge, which determines the slitting quality, the thickness of the lower knife, which determines the width accuracy of the workpiece to be slit, and the height dimensions of the knife.

For Metal foil

Dish slitter knife

Dish slitter knife

(Upper knife) Dish slitter knife

Dish slitter knife

(Lower knife) Dish slitter knife

Dish slitter knife

(Upper and Lower knife) Rotary chopper

Rotary chopper

knife/div> Shear blade

Shear bladeFor Film

Dish slitter knife

Dish slitter knife

(Upper knife) Dish slitter knife

Dish slitter knife

(Lower knife) Dish slitter knife

Dish slitter knife

(Upper and Lower knife) Score knife

Score knife

(Core cutter)

Dish slitter knife

(Upper knife)Paper and Corrugated paper (Carton) box

Circular knives for paper and pulp cutting are indispensable for slitting sheet materials.

Sharp slitting quality is required, so the knife edges are precisely ground and finished to customer specifications.

Knives for slitting corrugated sheet grooves are made of materials with excellent abrasion resistance for slitting strong and thick corrugated board, and can be manufactured in a variety of shapes to suit customer needs, with a uniform finish without crushing the slitting surface.

The high durability model (CIKC-1) and the paper dust reduction model (CIKC-2) have been approved as “Excellent Products” by Miyagi Prefecture.For Paper

Dish slitter knife

Dish slitter knife

(Upper knife) Dish slitter knife

Dish slitter knife

(Lower knife) Core cutter

Core cutter

(Score cutter) Score cutter

Score cutter

(Core cutter) Dish knife, Cup knife

Dish knife, Cup knife Log tissue cutter

Log tissue cutter

For Corrugated paper (Carton) box

Slotter knife

Slotter knife

(Upper knife) Slotter knife

Slotter knife

(Lower knife) Anvil knife

Anvil knife Slitter knife

Slitter knife

(for Carton box) Carbide corrugator

Carbide corrugator

knife Whetstone for Carbide

Whetstone for Carbide

corrugator knife Flap knife

Flap knife

Iron, Non-ferrous metals

Knives for cutting steel used in automobiles, shipbuilding, pipes, etc. and non-ferrous metals such as aluminium.

Various shapes of knives can be manufactured, including straight knives, circular knives and knives of different shapes.

We have a wide range of original steel materials for cutting tools.

The above steel materials are carefully selected and manufactured according to conditions such as the thickness and tension of the material to be cut.

We can also process the shape of the cutting edge into an arc shape and perform various surface treatments to prolong the life of the knife.

Our advanced processing technology, backed up by many years of experience, enables us to provide high-quality products.For Steel

Flying Cropshear

Flying Cropshear Side trimmer knife

Side trimmer knife Slitter knives(for Iron,

Slitter knives(for Iron,

non-ferrous metals) Spacer

Spacer Shear blade

Shear blade Scrap chopper

Scrap chopper Side clipping shear

Side clipping shear End shear

End shear Mechanically

Mechanically

Expanded Dice Disk cutter

Disk cutter Pipe Cutters

Pipe Cutters Up-cut shear

Up-cut shear Billet shear

Billet shear Die set

Die set Cold saw (for steel and

Cold saw (for steel and

non-ferrous metals)

For Non-ferrous metals

Up-cut shear

Up-cut shear Slitter knives (for steel

Slitter knives (for steel

and non-ferrous metals) Cold saw (for steel and

Cold saw (for steel and

non-ferrous metals)

Food

These specially shaped knives are used for thin slicing of meat for sukiyaki and shabu-shabu, and are suitable for high-speed cutting.

We have selected materials with excellent corrosion resistance to ensure long and safe use, and have earned a reputation for quality, technology, and service among our users.For Food

Tyre and Rubber

These knives are mainly used for cutting rubber used in tyres for cars, buses, aircraft, etc.

They have been used by tyre manufacturers for many years.

The material used is highly abrasion-resistant and ensures sharp cuts.

We also manufacture knives in a variety of shapes, from circular knives to long flat knives and special knives for removing the whiskers of tyres.

We make use of our accumulated know-how to provide products that meet the diverse needs of our customers with a variety of machining and heat treatment technologies.For Tyre

For Rubber

Wood working

These knives are used for chipping pulp logs and for grinding and cutting wood for veneer and plywood.

With the aim of improving quality and productivity, we have established a Veneer Rotary Knife Technical Team (known as VPT) to provide know-how on knife shapes and settings to plywood mills in Japan and abroad.For Wood working

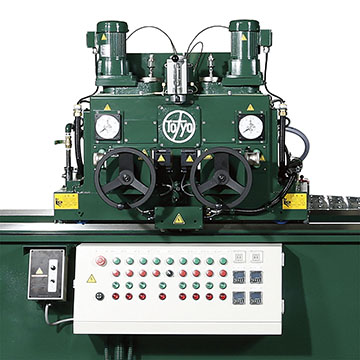

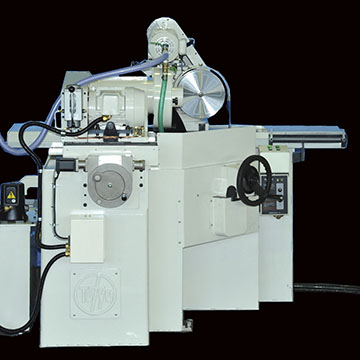

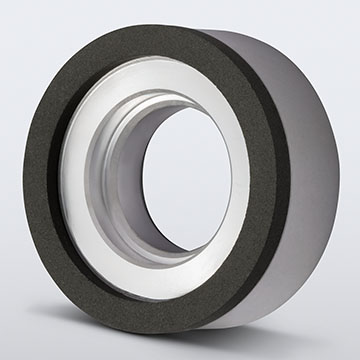

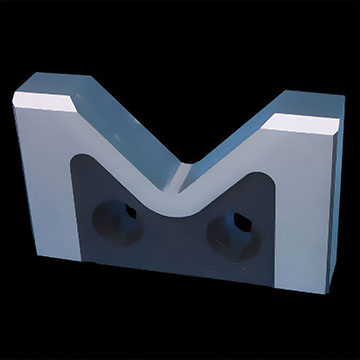

Grinding machine

The machine is used to regrind circular or flat knives that have been used by the customer. Semi-automation of the grinding process is available as an option.

For Straight knives

For Circular knives

High precision parts and cutter units

Good Design Award-winning holders for holding the upper blade of slitter knives, plate springs with unique technology, high-precision dies for LCD colour filters, guide rails and cutter units can all be manufactured to meet customer needs.

[Coating Die]

High-precision coating die made by using knife manufacturing technology cultivated over 90 years.

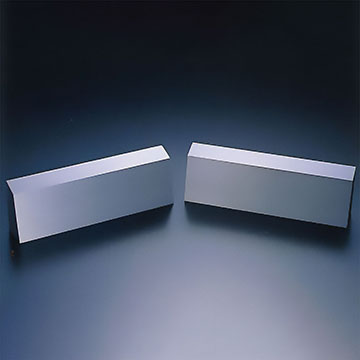

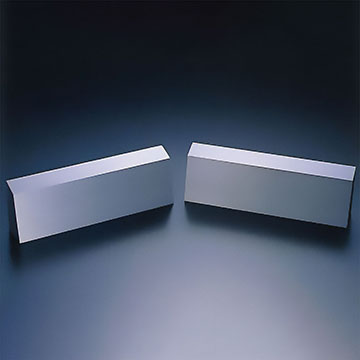

They are used in the coating processes of liquid crystal colour filters, optical films and magnetic tapes, and are the leading edge components of coating equipment.[Slide Way]

Slide Ways are rails used on the moving sliding surfaces of machine tools, injection moulding machines, forging machines, etc.

The hardened part can be multi-faceted and can be used for all types of sliding surfaces. For carburised products (material SCM), a hardened layer with an effective carburising depth of 1.2 mm can be obtained. All-steel products can also be manufactured.[Knife Holder & Plate Spring]

The holder is available in different specifications depending on the spring (coil spring or plate spring) set with the knife, but the plate spring specification is recommended to ensure stable contact pressure for improved cutting quality.

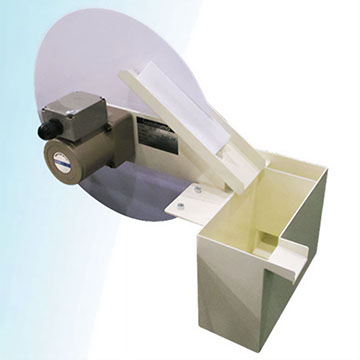

[Cutter Unit]

Our cutter units contribute to excellent reproducibility of slitting conditions and stable slitting quality.

We also offer laboratory units for research and development departments, which were developed from a different perspective from units for mass production slitters, for example, for “easy slitting to evaluate the performance of new materials” or “to find the best cutting method for commercialisation of newly developed materials.Machinery parts

Knife parts

High precision

High precision

movable holder Quick holder

Quick holder

(Standard, Bellock type) Preset holder

Preset holder

(Standard, Bellock type) Preset holder for removing

Preset holder for removing

the middle part

(Standard, Bellock type) Plate Spring

Plate Spring

Cutter unit

Cutter unit

Cutter unit

(For Dish knife) Cutter unit

Cutter unit

(For Gang knife) Ultra-fine width

Ultra-fine width

cutter unit (gang method) Cutter unit

Cutter unit

(Spring gang method) Cutter unit

Cutter unit

(Score-cutting method)

New product development information

New product information. Many cutter units are available for a variety of situations using our technology. Please contact us for more information.

Labo-unit

More information about this product

- TOYO KNIFE CO.,LTD.

- Industrial knives and cutters

- https://en.toyoknife.co.jp/

Web