-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrates

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine">

-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrates

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine

- The Equipment Related Business

- Electronic Device Business

- Photovoltaic Related Products

- Other Related Business

Electronic Device Business

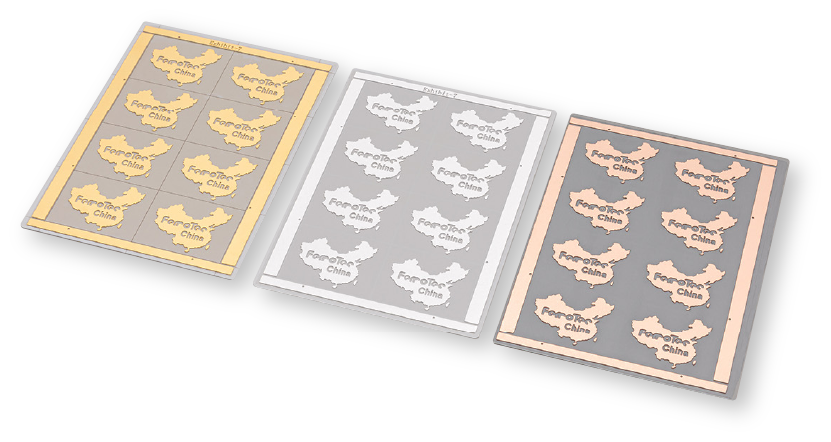

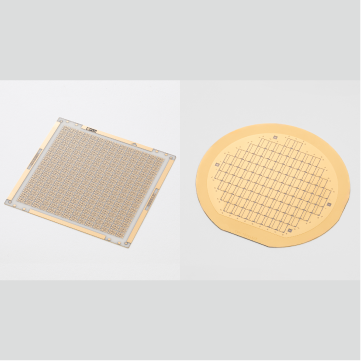

Power Electronic Substrates

DCB / AMB / DBA / DPC

Heat Dissipation and Insulation substrates that utilize our thermoelectric module manufacturing technology.

In our company’s Heat Dissipation and Insulation substrates, which utilize our thermoelectric module manufacturing technology, organic and metal substrates are commonly used for low-power household appliances and PCs. However, for insulated heat dissipation circuit substrates handling high power, substrates such as alumina oxide (Al₂O₃), aluminum nitride (AlN), and silicon nitride (Si₃N₄) are used.

Particularly, silicon nitride substrates are attracting attention for power modules in inverters/converters for electric vehicles. Our company has one of the world's largest production capacities for both conventional DCB (Direct Copper Bonding) substrates and AMB (Active Metal Brazing) substrates.

Additionally, we can manufacture DPC(Direct Plated Copper) substrates for data centers in the fifth-generation mobile communication system (5G), as well as DBA (Direct Bonded Aluminum) substrates used in parts requiring high reliability and heat dissipation characteristics, such as in cars, railways, and renewable energy.

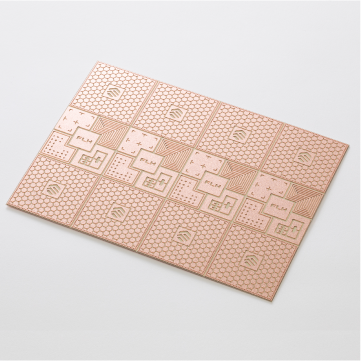

DCBDirect Copper Bonding

DCB Substrate

-

DCB (Direct Copper Bonding) substrates are electronic components in which copper plates are directly bonded to a ceramic substrate such as alumina (Al₂O₃) or alumina zirconia (Al₂O₃/ZrO₂), and then forming a copper circuit. They are widely used in power devices that require both electrical insulation and efficient heat dissipation.

Applications include industrial equipments, power supplies, home appliances, automotive components, and more.

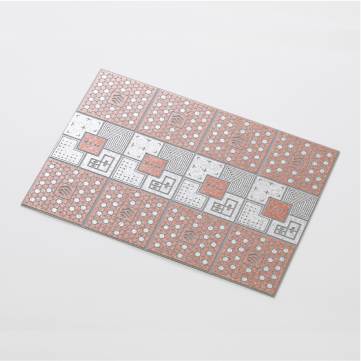

AMBActive Metal Brazing

AMB Substrate

-

AMB (Active Metal Brazing) substrates are electronic components in which copper plates are bonded to a ceramic substrate such as aluminum nitride (AlN) or silicon nitride (Si₃N₄) using active metal brazing materials, and then forming a copper circuit. Offering higher reliability and better heat dissipation than DCB substrates.

Applications include EVs, Electric trains, Power transmission systems, and industrial equipment, and more.

DBADirect Bonded Aluminum

DBA Substrate

-

DBA (Direct Bonded Aluminum) substrates are electronic components in which aluminum is directly bonded to a ceramic substrate such as aluminum nitride (AlN) or alumina (Al₂O₃), and then forming an aluminum circuit. With excellent thermal shock resistance and electrical characteristics, it is an ideal material for high-voltage, large-current power devices.

Applications include Renewable energy, Electric trains, EVs, and more.

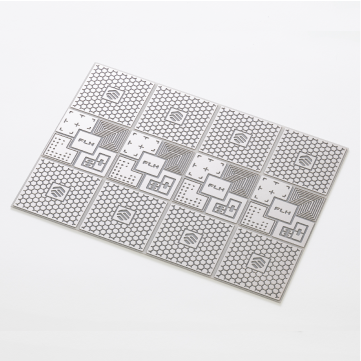

DPCDirect Plated Copper

DPC Substrate

-

DPC (Direct Plated Copper) substrates form high-precision copper circuit patterns on ceramic substrates using electroplating methods. Surface treatment improves anti-oxidation properties and solder wettability, resulting in better component performance and high reliability.

Applications include optical communication, high-power semiconductor laser, high-power LEDs, LiDAR, and more.

Silicon Nitride Ceramic Substrate

Silicon Nitride Ceramic Substrate

Major Applications of Power Semiconductors

Power transmission system

Reduction of power loss

Electric train

Miniaturization and weight reduction of inverter equipment

EV, HV

Miniaturization and weight reduction of cooling system

Production equipment

Reduction of power loss

Solar battery

Higher efficiency of power conditioner

Air conditioner

Energy saving

Personal computer

AC adapter miniaturized and built into the Personal computer

Server machine

Reduction of power loss

Power Semiconductor Substrate Location Map

FerroTecTokyo

Tokyo

-

Ferrotec Power Semiconductor Japan Corp.

FerroTecDongtai

Dongtai Factory

-

Jiangsu Ferrotec Semiconductor Technology Co. Ltd.

FerroTecShanghai

Shanghai Factory

FerroTecDongtai

Dongtai R&D Center

FerroTecSichuan

Sichuan Factory

FerroTecMalaysia

Malaysia Factory

Detailed Information on this Technology

- Ferrotec Power Semiconductor Japan Corp.

- Power Electronic Substrates

- https://ftpowersemi.co.jp/en/

Web