-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrates

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine">

-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrates

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine

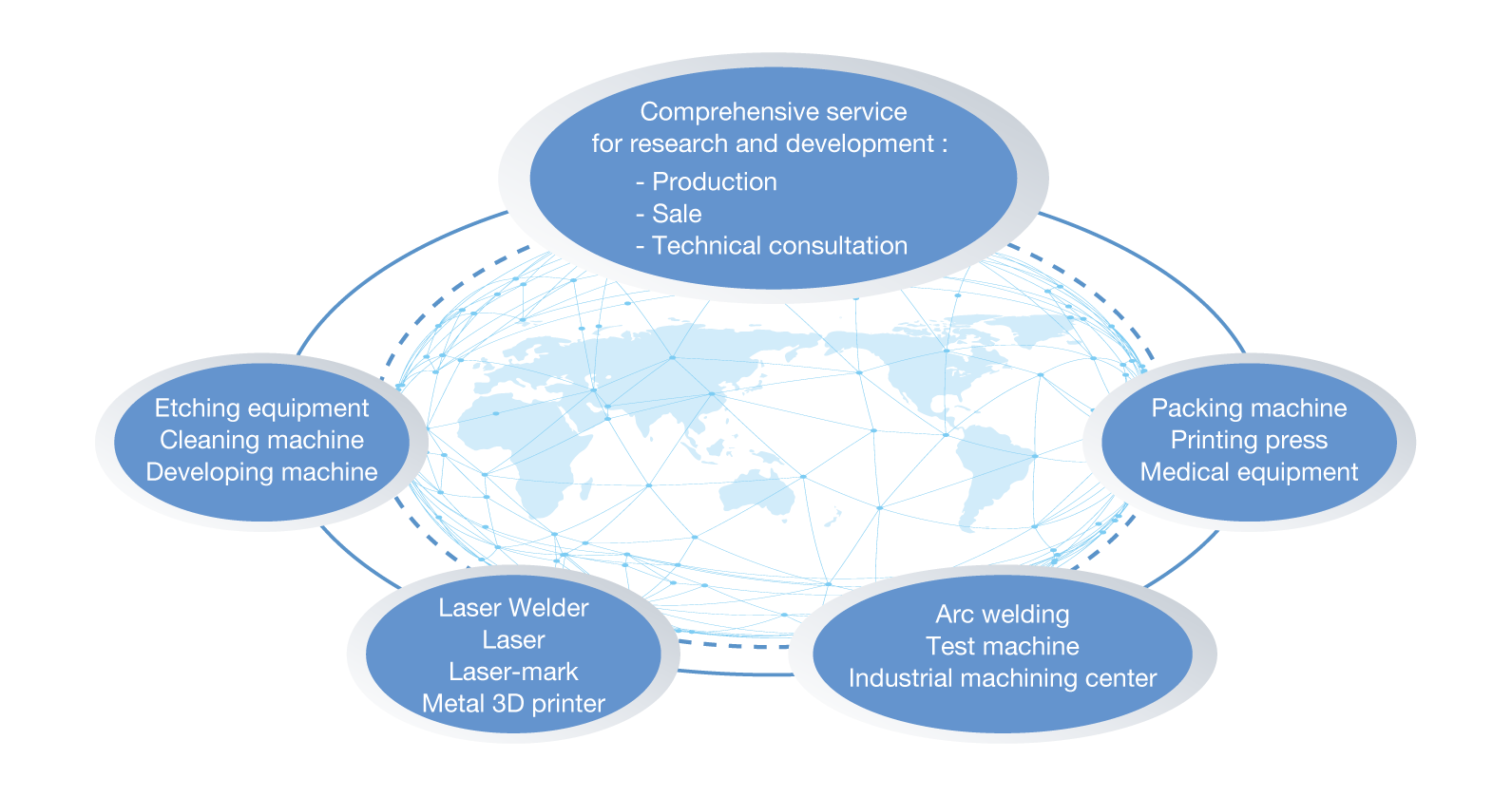

- The Equipment Related Business

- Electronic Device Business

- Photovoltaic Related Products

- Other Related Business

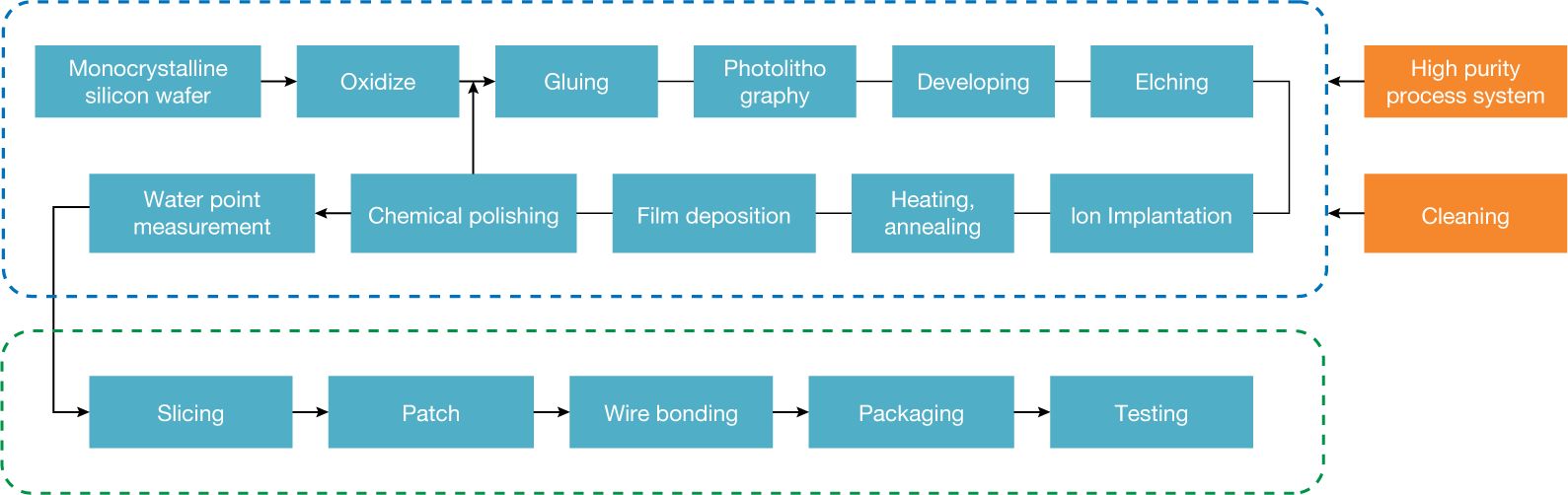

Electronic Device BusinessDevices Built Directly into Products

Chillers

A chiller (constant-temperature water circulator) is a device that supplies a circulating liquid such as water while cooling/heating to a preset temperature.

It is used to keep an object at a constant temperature such as heat sources in facilities and equipment via temperature-controlled circulating water.

Scope of application

Chiller aims to help achieve precise temperature control and transform into a perfect “leader in thermal solutions”. The best solution for intelligent and comfortable human life was provided.

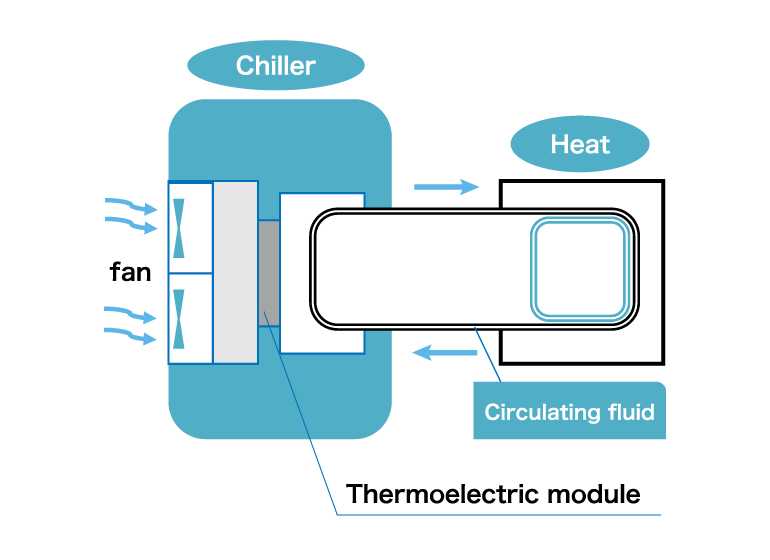

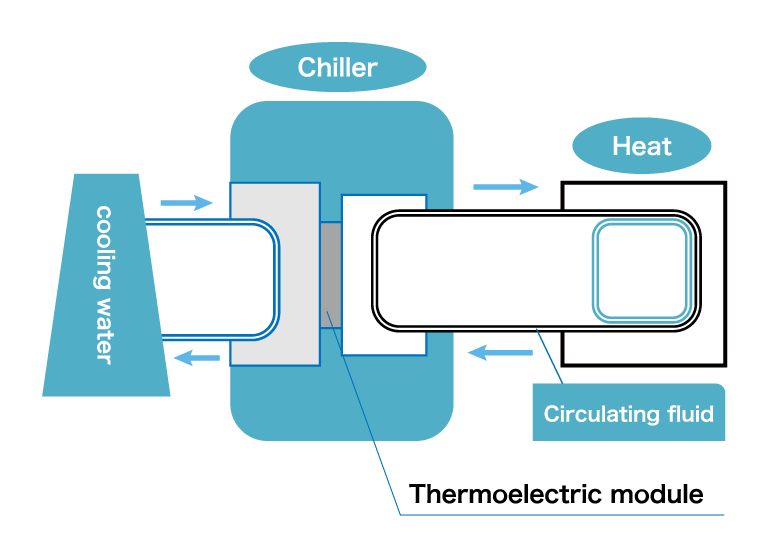

TEC series chiller (Air-cooled and Water-cooled)

Structure of “Thermoelectric module” type

Air-cooling

Air-cooling Water-cooling

Water-cooling

Thermoelectric Cooler (TEC) is a semiconductor device consisting of many small and effective heat pumps. By applying a low-voltage DC power source, the heat will be moved through the module from one side to the other. One module face, therefore, will be cooled while the opposite face simultaneously is heated. Multiple pairs of semiconductor components in series form a thermo-electric module assembly, heat absorption causes a decrease in temperature. Fast response and cold/hot surface conversion achieves high-precision temperature control.

The temperature range of FCP series semiconductor TEC controller is from 5 ℃ to 65 ℃, and the cooling power is from 300W to 1800W. By using air-cooled/water-cooled methods, semiconductor components of the TEC controllers have stable performance, highly accurate temperature control, compact size and closed system. The TEC controllers can achieve remote control of communication methods such as RS485/RS232, ETH and Ethernet, combined with multi-functional alarm system, security system, data transmission system. Ferrotec can provide custom lead products according to specific requirements.

Air-cooled

Water-cooled

Accessories (Cold plate system and TEC controller)

Ferrotec can provide variable TE modules and assemblies, used in all kinds of the cooling and heating applications.

Performance characteristics

Global leading independent R&D technology of thermoelectric modules significantly improves the performance. Excellent moisture-proof sealing design prevents moisture from entering the device. Optimized heat dissipation design, achieves efficient cooling performance. The isolated structural design enhances the seismic and impact resistance of TEC.

Compression series chiller (Air-cooled and Water-cooled)

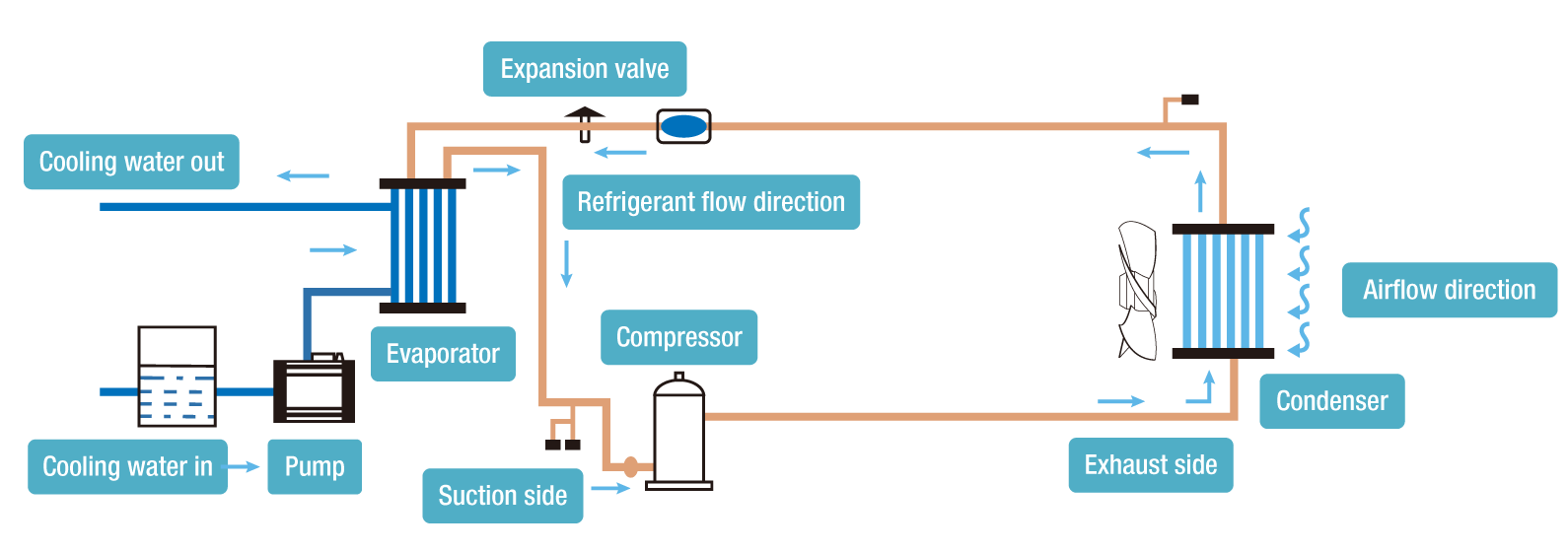

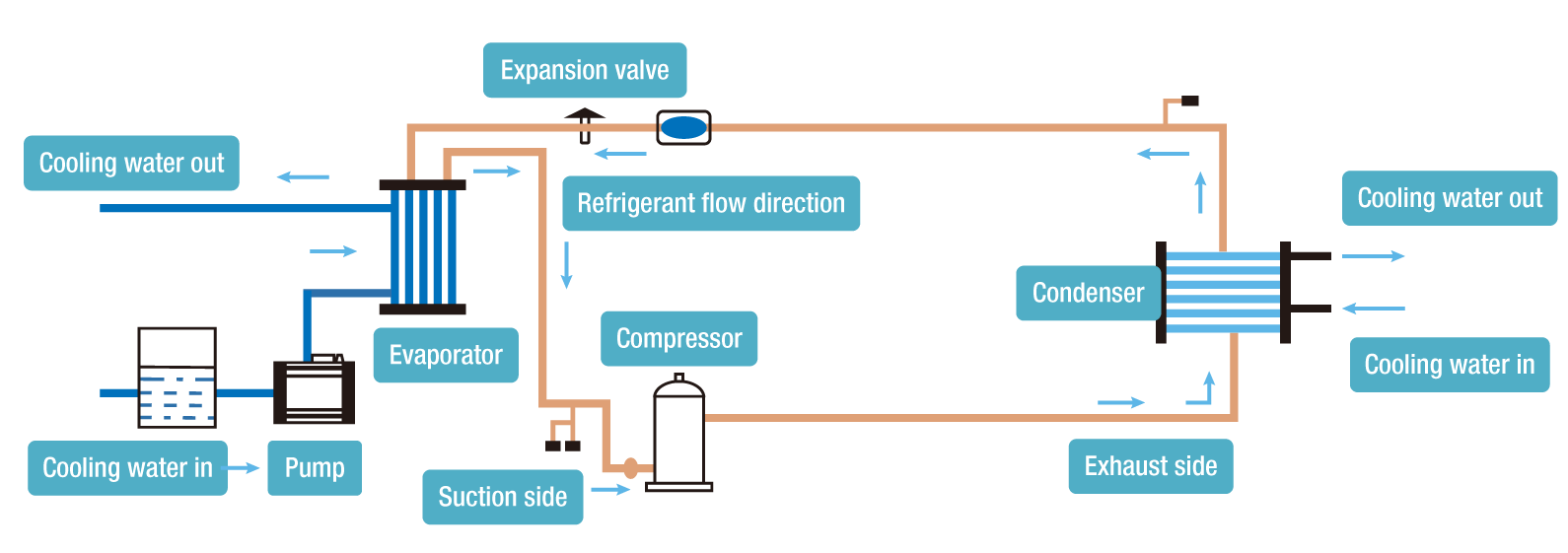

The refrigeration systems of vapor compression chiller generally consist of the compressor, the condenser, the throttling element, and the evaporator. The compressor compresses the refrigerant gas, outputs high-temperature and high-pressure refrigerant, and liquefies it into high-pressure and normal temperature fluid through the condenser (cooling water or air). Then, the fluid enters the throttling element (expansion valve or capillary tube, etc.) to reduce the pressure and temperature of the refrigerant simultaneously. The throttled refrigerant enters the evaporator and absorbs the heat of the cooled object. Afterwards, the refrigerant is sucked in and compressed by the compressor to circulate. The refrigerant is repeatedly compressed, condensed, expanded, and evaporated in the refrigeration system, continue to absorb heat and vaporize at the evaporator for cooling.

Performance characteristics

Accurate temperature control; reliable & stable; rapid cooling; environment friendly

Air-cooled

Water-cooled

Air-cooled

Water-cooled

Low temperature compression series chiller

This device adopts a frequency conversion temperature control method to improve energy efficiency and reduce energy consumption. The target cooling capacity can reach 3600W at -20 ℃. The device can meet the cooling needs of users. It has accurate temperature control technology and can be widely used from -20 ℃ to 80 ℃. The temperature is lapped with 0.1 ℃ tolerance.

Applications

Widely used in etching equipment of semiconductor industry, CMP(Mechanical Polishing), laboratory precision equipment, high precision testing instruments, cosmetic medicine equipment, solid state laser, mold, etc.

Thermal shock

FAM6031 is a precise thermal shock with a wider temperature range from -70 ℃ to 225℃. This device can provide very advanced temperature conversion testing capabilities. The fastest temperature conversion ranges from -55 ℃ to+125 ℃ for about 10 seconds. After long-term verification under multiple working conditions, it meets the requirements of various productions and engineering environments.

Applications

Reliability tests such as characteristic analysis, high and low temperature variation testing, temperature impact testing, failure analysis, etc. For example: chips, microelectronic devices, integrated circuits (SOC, FPGA, PLD, MC U, ADC/DAC, DSP, etc.) Flash, UFS, eMMC, PCBs, MC, Ms, MEMS, IGBT, sensors, small module components Optical communication (such as transceiver high and low temperature test, SFP Optical module high and low temperature test, etc.), other electronic industries, aerospace new materials, laboratory research, etc.

Advantages

Compact structure and mobile design;

Touch screen operation, human-machine interaction interface; Fast DUT temperature stabilization time;

The temperature can be lapped with 1 ℃ tolerance and air flow rate can reach up to 18SCFM. The defrosting design can quickly remove the accumulation of water vapor inside. It can meet the US Military Standard MIL system, the domestic military component GJB system and the JEDEC testing requirements.

Cascade refrigeration chiller

Quality assurance for core component suppliers Compressor supplier: Tecumseh; Filter: Danfoss; Electronic control display screen: Siemens, Schneider electric; Temperature resistant magnetic pump: wide temperature range, safe and leak free. Siemens display screen: core pressure parameters of refrigeration system, real time display of heat transfer oil temperature. Ferrotec can provide custom lead products according to requirements.

Closed cycle system

The entire system is a fully enclosed system, with no oil mist at high temperature and no absorption of water in the air at low temperature. The system will not increase pressure during running due to the high temperature, and will replenish thermal conductivity medium automatically at low temperature.

Safety System

The device has self diagnostic function and multiple security features: phase sequence phase failure protector, freezer overload protection. Continuous temperature control of -60 ℃ to 180 ℃ can be achieved.

Industrial series chiller (Air-cooled)

The compressor chiller uses a well-known brand compressor with stable and excellent performance. The equipment has two temperature control modes with multiple settings and fault display functions. The bottom universal wheels can be moved and installed easily. The side sheet metal buckle type installs dust screen for easy disassembly and regular cleaning of dust.

Applications

Suitable for environments with good temperature and humidity, energy-saving and environment friendly, with a wide range of temperature applications, stable quality and easy operation The selected compressor type chiller is mainly aimed at the industrial laser field and can be used in laser cutting, laser welding, laser marking, laser carving and other related equipments that use laser processing.