-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrate

- KSM bellows

- Cryotechnology, Polycold

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine">

-

- Vacuum Seals

- Quartz Products

- Ceramics

- SiC Parts (CVD-SiC)

- Silicon Parts

- EB Components

- Vacuum Coating System

- Silicon Wafers

- Reclaim Wafer

- Process Tools Parts Cleaning

- Single Crystal Silicon Ingot Puller

- Quartz Crucibles

- Ferrofluid

- Thermo-electric Modules

- Chillers

- Thermistors

- Power Electronic Substrate

- KSM bellows

- Cryotechnology, Polycold

- Photovoltaic Silicon

- Saw Blades

- Industrial Knives and Cutters

- CMS

- Industrial Laundry Machine

- The Equipment Related Business

- Electronic Device Business

- Ferrotec Europe GmbH Official Distribution

- Photovoltaic Related Products

- Other Related Business

The Equipment Related BusinessEssential Devices in the Manufacturing Process

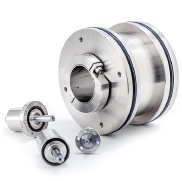

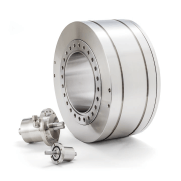

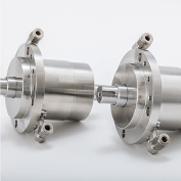

Vacuum Seals

Ensuring a Sealed Environment with no Contamination

The vacuum seals which use ferrofluid to enable transmission of rotational movement into the vacuum atmosphere are used in the manufacturing process of semiconductors, FPD, LED, and solar cells. They account for the company's core, and are used mainly in the etching and deposition processes of semiconductor wafers, as well as in the rotary mechanisms of delivery robots for FPD panels, isolating the sealed space from the outside, while precisely transmitting the necessary power for processing.

Please contact :

Ferrotec Europe GmbH

Mr. Joachim Schmied

Sales Representative

T: +49 7022 9270 202

E: jschmied@de.ferrotec.com

Industries that use these technologies

| Audio | Automotive | Electronics | Medical Equipment | Home Appliance | Other Industries | |

|---|---|---|---|---|---|---|

| The Equipment Related Business | ||||||

| Vacuum Seals |

|

|

|

|||

| Quartz Products |

|

|

|

|||

| Ceramics |

|

|

|

|||

| SiC Parts (CVD-SiC) |

|

|

|

|

||

| Silicon Parts |

|

|

|

|||

| EB Components |

|

|

||||

| Vacuum Coating System |

|

|

||||

| Silicon Wafers |

|

|||||

| Process Tools Parts Cleaning | ||||||

| Electronic Device Business | ||||||

| Ferrofluid |

|

|

|

|

|

|

| Thermo-electric Modules |

|

|

|

|

||

| Power Electronic Substrate |

|

|

|

|

||

Detailed Information on this Technology

- Ferrotec USA

- Ferrotec Ferrofluidic Seals and Vacuum Rotary Feedthrough Solutions

- https://seals.ferrotec.com

Web

Manufacturing Bases

Case Examples of Vacuum Seal

Etching Equipment

Etching is a surface processing method that uses the corrosive effect of a chemical solution or reactive gas. In semiconductor manufacturing it is used as a method to remove thin films in the patterning process of wafers. There is dry etching, which uses gas turned into plasma to accelerate ions to scrape away film by scientific reaction, and wet etching, which utilizes the corrosive effects of acid and alkali.